Production technology

Tubular heating elements are exclusively manufactured according to the Oakley-Kanthal technology. They have a number of remarkable features which have been achieved by consistent use of high quality materials and large experience of manufacturing this kind of products. The most important advantages are:

- high and stable quality of electric parameters as a result of central location of the heating coil;

- high operational durability of tubular heating elements as a result of use of homogeneous insulation filler made from the highest quality magnesium oxide (MgO) and use of the highest quality resistance wire;

- high surface load and high permissible maximum surface temperatures as a result of use of the highest quality tubes made from stainless steel.

Tubular heating elements produced by SELFA meet technical standards of PN-EN 60335-1. Most of our products received certificates that entitle to use mark “VDE”.

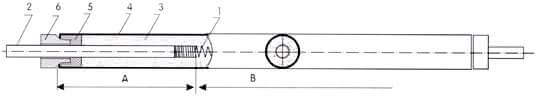

Structure of tubular heating elements

A – inactive length (unheated)

B – effective length (heated)

1 – heating coil

2 – terminal point

3 – insulation powder

4 – sheath metal tube

5 – sealing

6 – ceramic insulation

Parameters of manufactured heating elements

STANDARD DIMENSIONS OF HEATING ELEMENTS AND MATERIAL OF THE SHEATH TUBE

| Material of the sheath tube | ||||

| Ø [mm] | cooper | steel(C10, IF25) | stal nierdzewna (AISI 304, AISI 316, AISI 321, Incoloy 800, Incoloy 825) | Length [mm] |

| 6,4 | + | + | + | 200 – 3350 |

| 8 | + | – | – | 200 – 3500 |

| 8,35 | – | – | + | 200 – 6000 |

| 8,5 | + | + | + | 200 – 6850 |

| 10 | – | – | + | 200 – 3450 |

| 13 | – | – | + | 200 – 6850 |

| 16 | – | – | + | 200 – 6860 |

Heating elements for special orders can be manufactured in various lengths and diameters.

Diameter size tolerance will remain at the current level of ±0,1 mm.

Standard length tolerance is ±2 %, but for special orders it can be decreased to ±1mm.

Rated voltage nad power

Both rated voltage and power are electric parameters dependent on individual requirements of our clients.

Typically used voltages are:

24V, 42V, 48V, 65V, 110V, 127V, 220V, 230V, 380V, 400V, 500V

Rated power of a single heating element can be in the range from a few tens of W to a few kW. According to PN-EN 60335-1:1999 specification typical rated power tolerance is +5/-10%.

Additional information about rated voltage and power of heating elements can be found here.

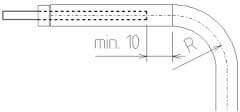

Bending and length of dead parts

Each tubular heating element has on both ends dead parts. Length of dead parts varies and depends on individual requirements of our clients. The minimal length of dead part is ~25 mm.

Tubular heating elements are bent according to individual requirements of our customers expressed by samples and/or drawings. The minimal radius of bending depends on the diameter of heating element and the material of the sheath tube. In some cases it can be even equal to the half of external diameter of the sheath

Heating elements may never be bent in places where the dead parts end lest the hot terminals should damage heating element insulation.